90 days...

N0 Payments!

90 days... N0 Payments!

Click to GET STARTED

Click to GET STARTED

90 days...

N0 Payments!

90 days... N0 Payments!

Click to GET STARTED

Click to GET STARTED

Sollant has customized a matching air compressor for the cutting industry, which can meet the demanding requirements of various laser cutting equipment for water, oil, and particles in compressed air. The product adopts five-stage filtration and non-heat regeneration adsorption dryer. Pressure dew points up to -20 ° C ~ 70 ° C.

Scroll down for more information.

Machine Features

• System has the design advantage of small size.

• Low cost but high quality with long service life.

• They are easier to maintain and repair.

• Lower noise of air compressor for laser cutting industry.

• Few parts, easy assembly for clients.

• Air compressor for laser cutting machine low cost.

-Saves time: Air compressor for laser cutting can save you a great deal of time. It cuts through the materials faster than the other laser cutters. Also, the blowing mechanism of these laser cutters speeds up the whole process.

-Reduces waste: Air compressor for laser cutting helps to reduce waste of the material. This is because laser beams are able to focus only on the target area of the material. The surrounding patches won’t be affected by the cutting process.

-Deeper and precise cuts: The laser beam has the power to penetrate deep into the material and obtain quality cuts

Why choose A 4-IN-1 air compressor?

(1). Integrated design with beautiful appearance, fewer parts, and connectors reduce the possibility of unit failure and leakage; direct discharge of dry compressed air, fully guarantee the quality of user terminal gas; greatly save customer installation costs and use space.

(2). With new modular design structure, compact layout, ready to install and work.

(3). After strict testing of the unit, the vibration value of the unit is far lower than the international standard.

(4). The integrated and optimized pipeline design reduces the length and number of pipelines, thereby reducing the incidence of pipeline leakage and internal losses caused by the pipeline system.

(5). Adopting a freeze dryer with excellent performance, a compact rotary refrigeration compressor, and a high cooling capacity configuration scheme to ensure reliable operation under high-temperature conditions.

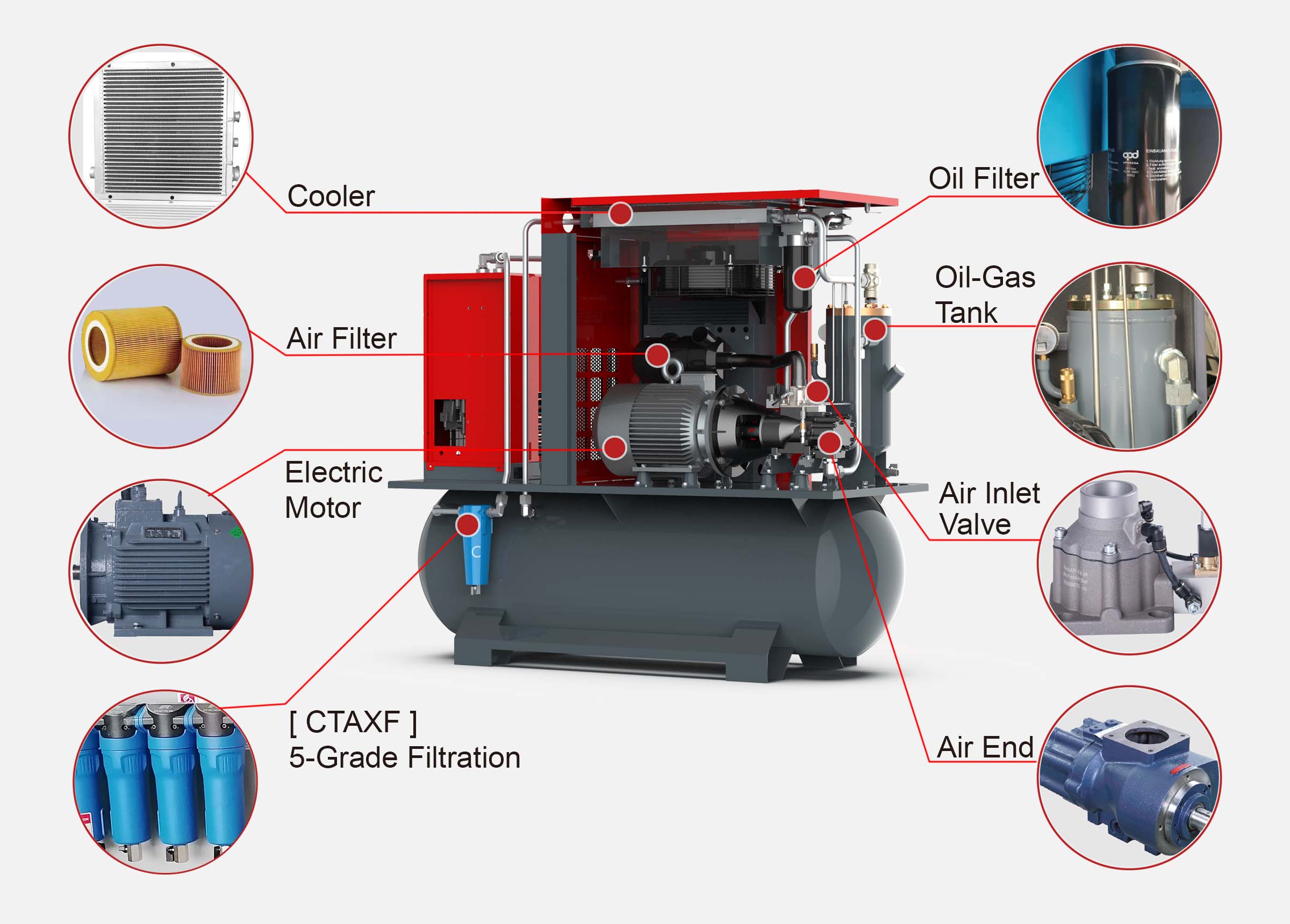

1. Screw Air Compressor:

♦ Motor

Adopt high-efficiency and energy-saving IE4 motor

♦ Air End

New 20CrMrTi (alloy steel) two-stage rotor material, 5:6 tooth rotor profile, higher strength, and better energy efficiency. The new bearing structure, using copper bearings greatly improves the service life of

the machine body

♦ Oil And Gas Tanks

The oil and gas separation tank is designed with an external oil separation core for easy maintenance

♦ Oil Separator

The oil separation core adopts the MAN brand, and the oil and gas separation effect is better

2. Refrigerated Air Dryers:

High-quality compressed air for your equipment and processes

The aluminum plate-fin series of refrigerated dryers ensures dry compressed air, prolongs the service life of your equipment, and ensures excellent production quality. Efficient water removal prevents corrosion in the compressed air network and in the air tools. All in all, it reduces your maintenance costs and improves your overall level of production with complete peace of mind.

♦ Excellent performance

Excellent performance

High-efficiency plate-fin heat exchanger

Low relative humidity of outlet air

Professional water removal function

Dew point 2-10°C

♦ Energy saving and carbon reduction

Energy saving and carbon reduction

50% reduction in energy consumption

compared to shell and tube dryers

Optimized refrigeration system

3. Precision Filter:

Test compressed air quality according to lSO 8573

♦ Residual oil measurement – OIL-Check 400

Continuously and accurately measure the residual oil content in the form of steam from 0.001 mg/m’ to 2.5 mg/m’, Class 1 compressed air quality can be monitored through a low detection limit of 0.001mg/m'(ISO 8573)

♦ Particle counter PC 400

The high-precision optical particle counter PC 400 can measure particles as low as0.1 um in size, so it is suitable for monitoring the quality of compressed air at level 1(ISO 8573)

♦ Residual humidity – dew point sensor FA 510

FA 510 can measure the pressure dew point up to – 80Cd. At this time, continuous measurement can also ensure that the alarm will be triggered immediately when the compressed air dryer fails.

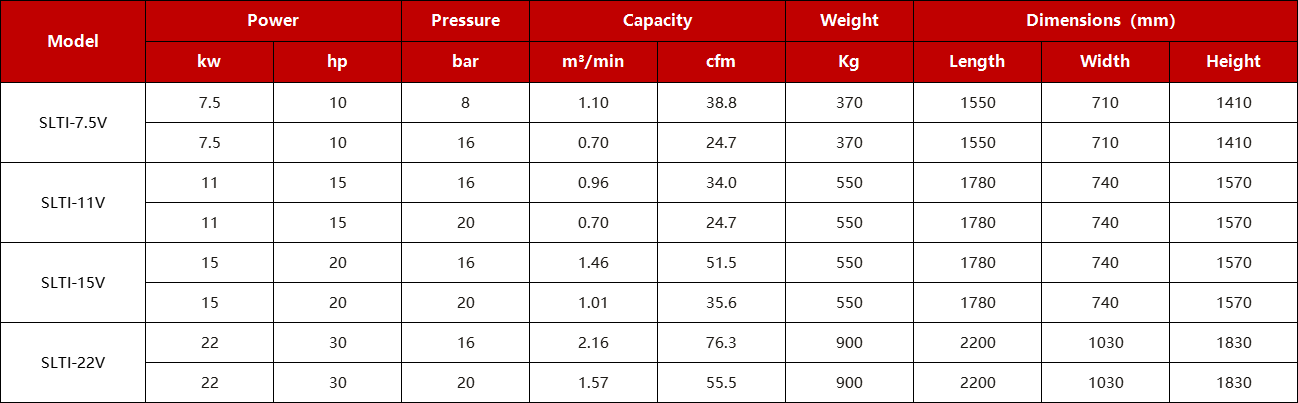

4. Technical Parameters:

Copyright © 2025 Lone Star Cutting Solutions. All Rights Reserved.

Designed, Developed & Hosted by Duncan Multi-Media.